If you want consistent, repeatable colors when modifying your natural dyeing with iron, iron water is not the thing to use. Move along and search online for a recipe to make an iron acetate mordant for anything that requires measurable results. However, if you want to introduce a little bit of chaos, surprise, and pure chemical magic into your practice, have I got the recipe for you.

Iron water is incredibly simple to make. The hardest part for me was sourcing rusty iron because it turns out you can’t buy that from your local hardware store and the streets of Dublin are suspiciously tidy and rusty-nail free on the one week when you’re trying to find them. However, Orlaith came through for me and supplied me with a lovely bag of rusty nails and metal pieces. (Get yourself a friend who doesn’t think it’s weird when you ask for rusty nails in bulk.)

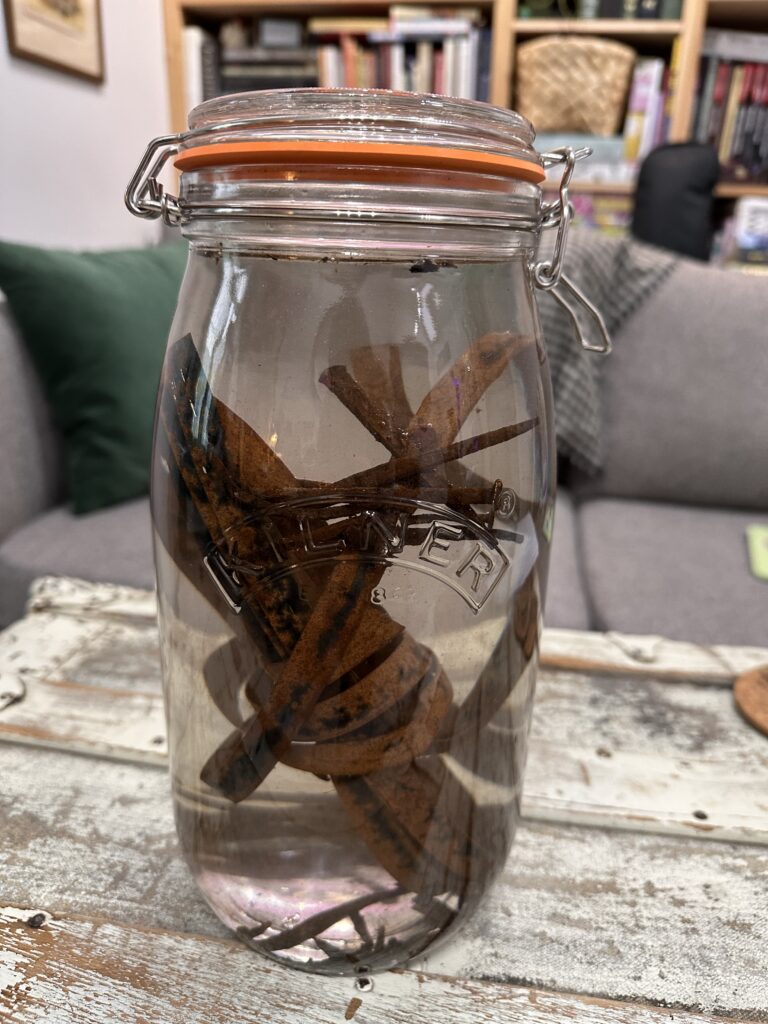

Once you have your rusted iron, all you need to do is place that into a container and fill it the rest of the way up with 1 part vinegar to 3 parts water. Give it a quick stir and then leave it alone for 3-5 days or until it starts to look nice and rusty.

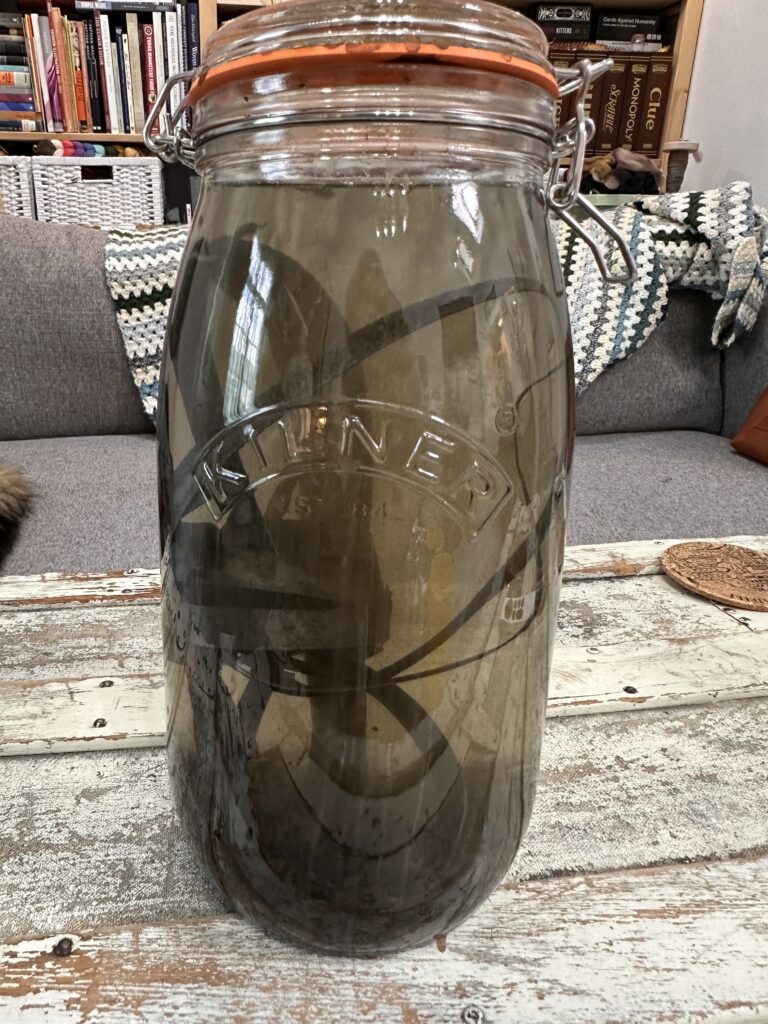

Obviously, because I am who I am, I did not leave my iron water alone for 3-5 days. Instead I worried over it like a new pet and photographed it every day, for science, before forgetting about it and leaving it alone while I went on a little vacation. I came home to find that it had done exactly what it was supposed to do without any intervention from me. Trust the process folks.

The results of dyeing with my iron water (left) compared to iron acetate (right). Interestingly, the pitcher with my iron water was a lighter, more rusty brown shade but produced far darker, nearly black results on the textiles when they were wet. The iron acetate water turned nearly black, but gave more subtle, greyish-brown saddening results when the textiles were still wet. This led me to believe that the iron water I used was a much stronger concentration of iron than the iron acetate mixture where I was able to measure out exactly 2% iron. It would be a fun experiment to do this same test each day that the iron water is maturing and see if it gets stronger over time, or if it reaches a point and then stays roughly consistent. Although, with all the steps of mordanting and dyeing, this experiment is beyond my current space that I have available (both physical and brain).

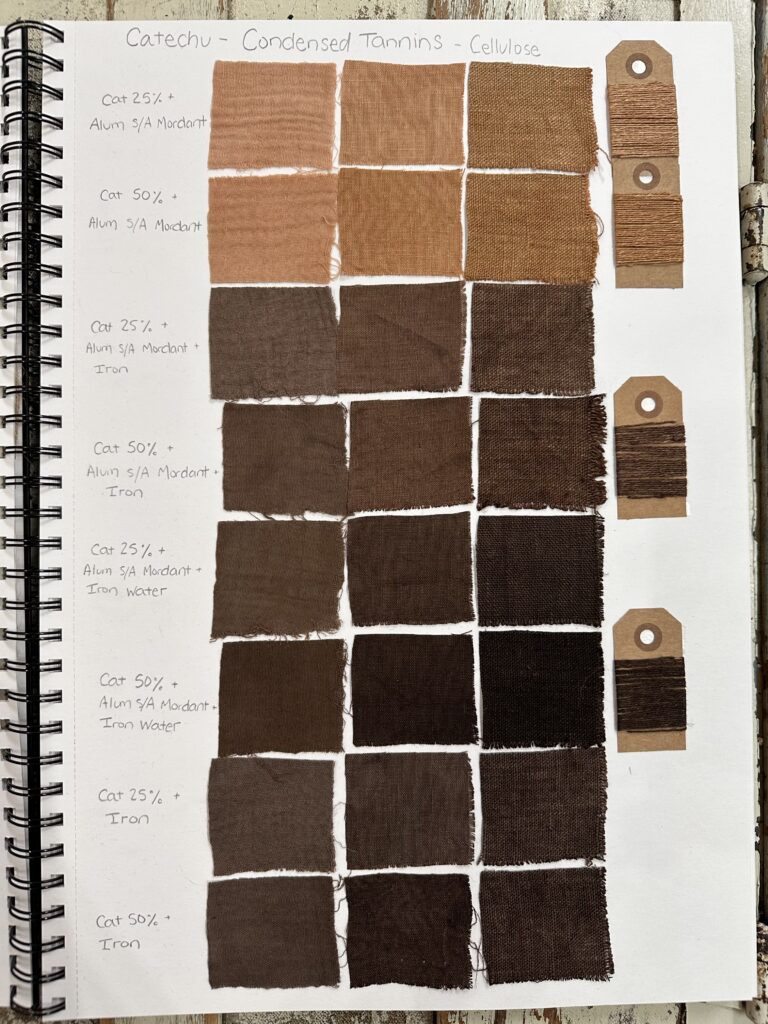

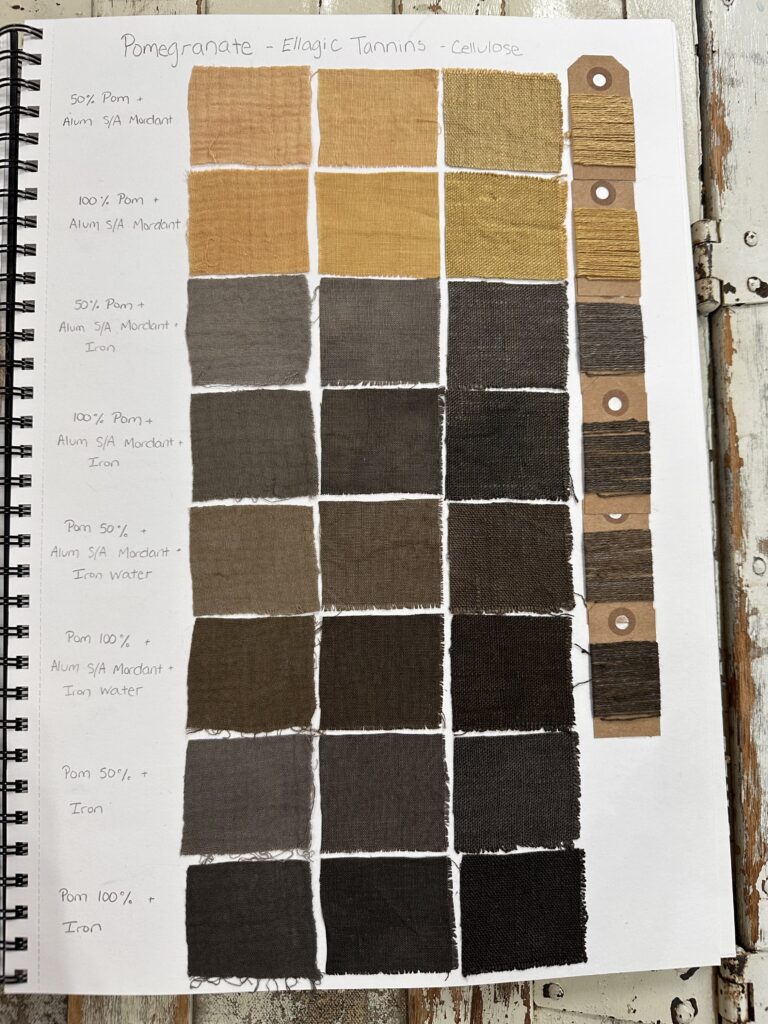

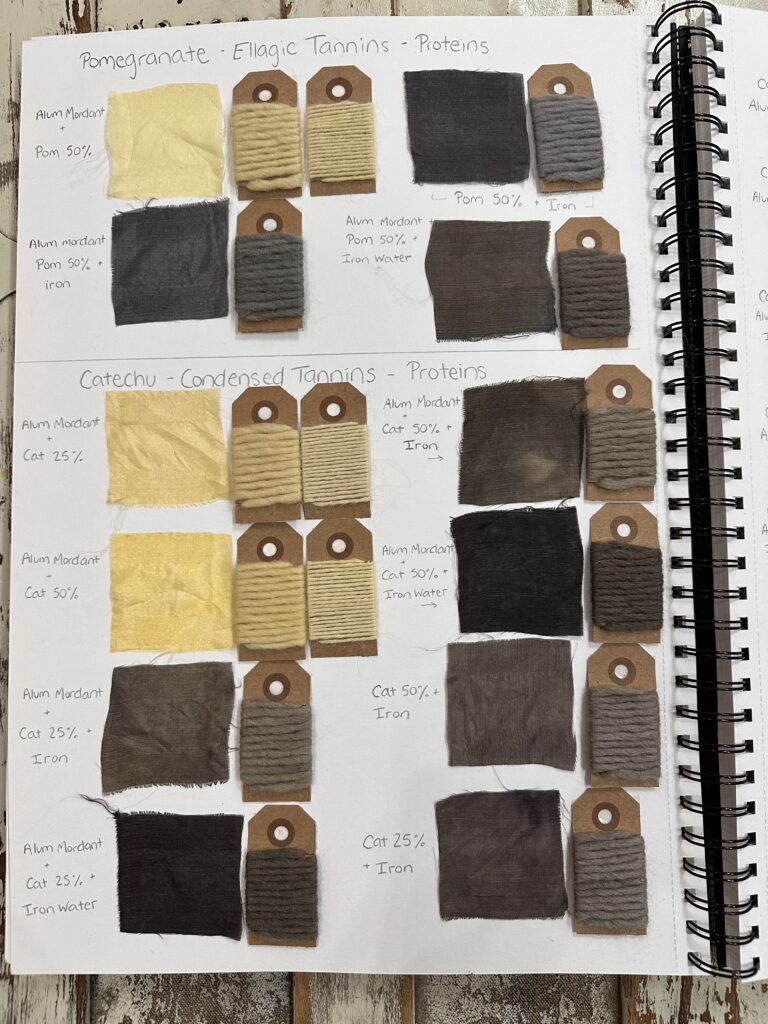

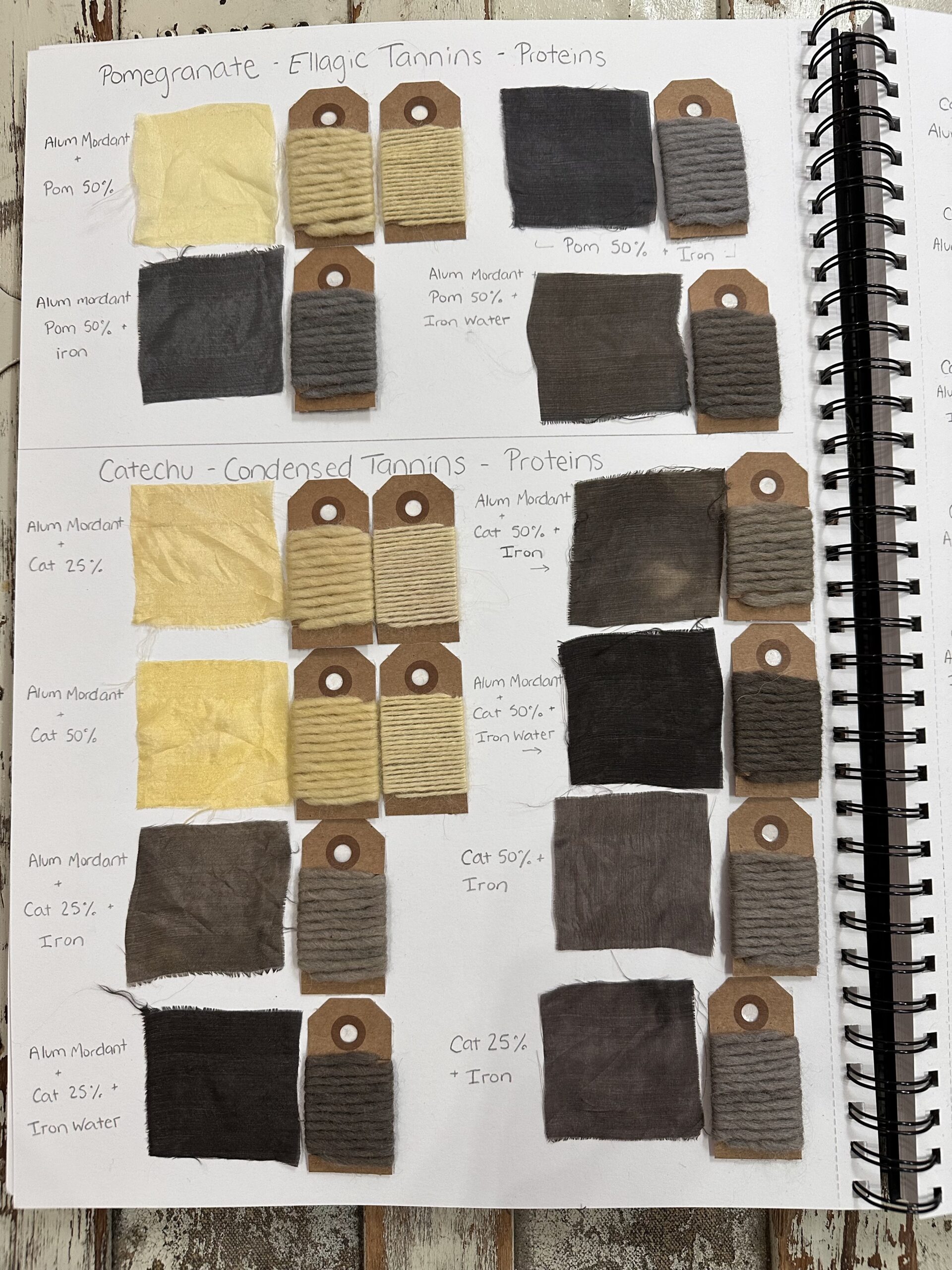

After dyeing all of my samples and letting them dry, I organized them into my portfolio. Now that everything is dry, it’s interesting to note that the differences between the iron water and the iron acetate are less clear cut. The iron water samples lightened several shades while they dried, while the iron acetate samples darkened over time. The iron water samples that, when wet, had looked like black textiles turned into dark browns and dark greens.

The answer is not just ‘my iron water was stronger’. The iron water did produce darker shades on some of the silk and wool samples. But, on the cellulose samples, the iron water gave warmer, rustier tones that fit in more harmoniously with the rainbow of natural dye colours I am discovering. The iron acetate has a greyish undertone in nearly all of the samples. The difference is subtle, but it’s there.

The iron acetate is easier to use if you’re wanting a measurable result. I knew I had a 2% mixture of iron acetate, and I know I can create that same mixture over and over and always get the same grey tones. However, the natural, earthy, rusty tones that came from the iron water are appealing enough that I know I’ll be letting a little more chaos magic into my dyeing in the future.

Leave a Reply