Mordanting is a preparation process used in textile dyeing to improve the uptake and colorfastness of dyes in fibres. The term “mordant” comes from the Latin word “mordere,” which means “to bite.”, so you get me afflicting your mind’s eye with the idea of little chemical agents biting down all eager to get slathered in colour – forming a chemical bond with both the textile fiber and the dye, helping to anchor the dye molecules to the fabric. That is probably not an image you (or I) wanted, but here we are.

Mordanting is the third step of dyeing, the first of which are important to know for this step, since it affects how you go about it. They are

- Determine what kind of material are you working with? Is it

Plant based (cellulose) fiber – Fabric that is derived from plant materials. Some examples include cotton, linen, hemp, and rayon.

ORProtein fiber Fabric that is derived from animal materials. Some examples include leather, wool, and silk.

- Weigh the material you wish to dye.

This is more important the more you try to achieve or repeat a specific look – in our case we’re experimenting so it’s not so important, but just remember you need the dry WOF/WOY (Weight Of Fabric/Yarn) to determine how much mordant and dyestuff to use. - Scour (wash carefully – this is another post per fibre)

- Mordant

The mordanting process involves treating the fibre in some way before applying the dye. Common mordants include mettalic salts like alum (potassium aluminum sulfate), iron (ferrous sulphate), copper (copper sulphate), tin, and chrome. The choice of mordant depends on the type of dye and the fiber being dyed. They are added at different percentages of the the WOF/WOY, depending on the end effect required. I typically use 12% alum for example or a 5% iron.

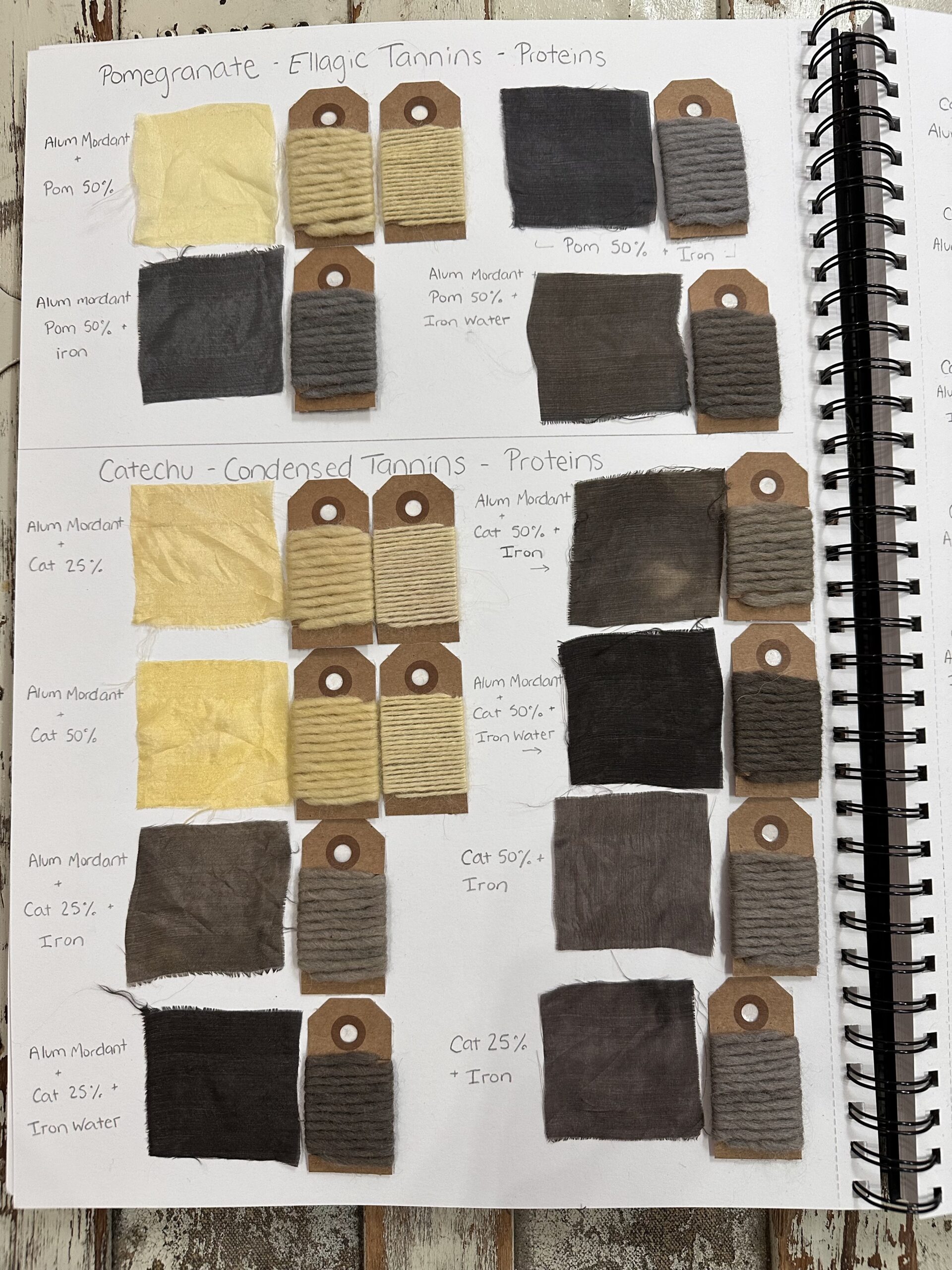

The use of mordants enhances the permanence and brilliance of colors AND can also produce variations in color shades, so the choice of mordant can be a creative decision for textile artists and dyers. Iron is famous for “saddening” or darkening any colour you want to dye with.

Tin and Iron can both be very harsh on fibres and great care should be taken when disposing of mordant baths made with metallic salts. Copper is great to achive nice greens, the green in the basket below is a chrome mordanted wool with no other dye added. the dark orange is iron treated, it feels slightly crispy to the touch and the duller beige beside that is a oak gall tannin mordanted wool. the more natural cream coloured wool is alum mordanted.

A lot of natural dyes simply will not adhere to natural fibres properly, particularly protein fibres, without the use of a mordant or fixative. It’s really frustrating if you make up a lovely dye bath and it looks like everything has gone great and then the colour just washes out to a mere hint of itself at the end.

If you are using PROTEIN fibres you have a lot of options. Easiest is to stick with alum (Potassium Alum) and optionally Cream of Tartar when mordanting wool – it’s safe to use, relatively easy to get and not expensive, and, importantly, easy to dispose of. Alum gives “truest” colours, it doesn’t tend to add any colour of its own so colours tend to be clear and bright.

Potassium alum, potash alum, or potassium aluminium sulfate is double sulfate of potassium and aluminium, with chemical formula KAl(SO4)2. Often called just alum, it is commonly used in water purification, leather tanning, dyeing, pickling and food preservation. Potassium alum has been known about and used since at least 1500 BCE. It is used in Gioanventura Rosetti’s Plichto de L’arte de Tentori. It is THE most common mordanting agent in dye recreations. You use alum at usually between 10% – 15% of the dry WOF ratio. The more of your mordant you add the more strongly the dye should take but also the stickier your wool will feel.

You may also wish to use Cream of Tartar in your mordanting process, but you must pay attention to the dye stuff you want to use if you do – later period heartwoods from the Americas will not develop properly if you use it. Home sources, older dyestuffs tend to respond well. It WILL affect your colour as it acidifies, but it softens wool fibres helping alum to work better and takes away some of the vaguely unpleasant stickiness wool gets after alum.

If you are using CELLULOSE fibres it can be a bit trickier. A period way would have been to use tannins (this will also colour the fibre somewhat) and then dye. Alum works on some cellulose fibres pretty well, and there is a modern alum acetate, but this is harsh, hard to dispose of and I don’t tend to use it myself.

Mordanting is best done overnight.

Leave a Reply